Poultices for desalination: Difference between revisions

No edit summary |

No edit summary |

||

| (35 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

Author: [[user:Hschwarz|Hans-Jürgen Schwarz]] | Author: [[user:Hschwarz|Hans-Jürgen Schwarz]] | ||

<br> | <br> | ||

English version by [[user=SLeithaeuser|Sandra | English version by [[user=SLeithaeuser|Sandra Leithäuser]] <br> | ||

back to [[Desalination]] <br> | back to [[Desalination]] <br> | ||

== [[Permanently wet poultice]] == | == [[Permanently wet poultice]] == | ||

The poultice | The poultice is kept moist during the application time. There is no, or only a small, moisture gradient so that salt transport is mainly due to diffusion. After some time, a salt concentration equilibrium is established between poultice and substrate. Permanently wet poultices should only be used in cases where a moisture gradient cannot be established, for example, a very damp wall. However, there are risks to this method, such that if a large area is being treated, salt may migrate back into areas of the substrate with a lower salt concentration. Also, long application times may enhance the development of microorganisms in the poultice material. | ||

== [[Drying Poultice]] == | == [[Drying Poultice]] == | ||

In this case, the poultice is allowed to dry out more or less completely, depending on the climatic conditions during application. Capillary transport and diffusion usually result in a flow towards the poultice, because of the rectified moisture gradient (first from the poultice to the substrate and then back into the poultice) as well as the salt concentration gradient. If the porosity of poultice and substrate is well matched, the capillary transport can be predominant. When gradual drying takes place, salts accumulate in the poultice material. | |||

For the treatment of relatively poorly soluble salts (e.g. gypsum) a combination of the two methods | For the treatment of relatively poorly soluble salts (e.g., gypsum) a combination of the two methods can be used. To begin with a permanently wet poultice is applied to dissolve the gypsum, then a drying poultice is applied. | ||

Due to the sheer number of influencing factors and their variation during the desalination treatment, no universally applicable procedure can be | Due to the sheer number of influencing factors and their variation during the desalination treatment, no universally applicable procedure can be recommended. Only approximate values can be provided, and these have to be tailored to each individual case. | ||

Desalination poultices | Desalination poultices can be prepared from one or more components (listed below)and with deionized water to an appropriate consistency for application. | ||

* | Poultice materials that can be used are: | ||

* | *Swellable materials from organic origin, no sealing properties, high water absorption and high water retention capacity (e.g., cellulose, paper pulp, aqueous gels). | ||

* | *Mineral components with high specific surface area and a good ion exchange and adsorption properties (e.g., clay minerals and their mixtures, such as kaolin, bentonite etc.). | ||

*Inert fillers (in combination with substances of the previous groups) to give the mixture properties such as stability, high porosity or a loose structure, to improve workability or decrease shrinkage, such as quartz sand, quartz flour, silica, good quality sand-rich in quartz, lightweight aggregates or equivalent). | |||

*Other components that are highly porous, absorbent, flexible and inert mats and fleeces, such as foams, paper, textiles, etc. | |||

Table 1 lists the materials recommended by the WTA. | |||

== [[The injection poultice procedure]] == | == [[The injection poultice procedure]] == | ||

This procedure <bib id="Friese.etal:1993" /> is carried out by introducing the water for desalination | This procedure <bib id="Friese.etal:1993" /> is carried out by introducing the water for desalination via the interior of the wall. For this purpose holes are drilled into the masonry or its joints and a pipe is fitted through it to the center of the wall or just beyond the salt contaminated layer, and water is sent through it. At the injection point, the water disperses spherically and when two water- spheres of adjacent injection points overlap, a capillary water flow is generated from the interior of the wall towards the surface of the masonry on which a poultice is applied. A disadvantage, however, is that holes need to be drilled and this is a decision that needs serious evaluation with regards to ethics and history of the building. | ||

When using this method it is very important to assess the structure of the wall well enough and to know exactly which materials were used | When using this method it is very important to assess the structure of the wall well enough and to know exactly which materials were used and if the masonry has a different core. The introduction of water into the structure could lead to an increase in weight, leakage of unknown substances, water seepage in other areas of the building, or uncontrollable swelling. Also the amount of water introduced needs to be controlled. | ||

{| width="100%" cell spacing="0" cellpadding="4" border="2" | {| width="100%" cell spacing="0" cellpadding="4" border="2" | ||

|+ | |+Table 1: '''Most frequently used poultices '''(in accordance with <bib id="WTA_3-13-01_D:2003"/>) | ||

|- | |- | ||

| bgcolor="#ffff99" align="center" | '''Poultice composition''' | | bgcolor="#ffff99" align="center" | '''Poultice composition''' | ||

| Line 43: | Line 37: | ||

| bgcolor="#ffff99" align="center" | '''Disadvantages''' | | bgcolor="#ffff99" align="center" | '''Disadvantages''' | ||

|- | |- | ||

| bgcolor="#ccffcc" | Pure cellulose | | bgcolor="#ccffcc" | Pure cellulose fibers of different length | ||

| bgcolor="#ccffcc" | - pH-neutral<br>- flexible, soft, adherent<br>- high water absorption | | bgcolor="#ccffcc" | - pH-neutral<br>- flexible, soft, adherent<br>- high water absorption | ||

| bgcolor="#ccffcc" | - low stability<br>- risk of | | bgcolor="#ccffcc" | - low stability<br>- risk of mold formation | ||

|- | |- | ||

| bgcolor="#ccffcc" | Bentonite, | | bgcolor="#ccffcc" | Bentonite, attapulgite, kaolin, pure or mixed with cellulose | ||

| bgcolor= "#ccffcc"| - high water retention capacity<br>- kaolin: in solution almost neutral,hardly any alkali can be | | bgcolor= "#ccffcc"| - high water retention capacity<br>- kaolin: in solution almost neutral,hardly any alkali can be mobilized | ||

| bgcolor="#ccffcc" | - extremely hard when high clay mineral content is present<br>- sometimes increased pH- values<br>- kaolin: risk of white residue on the surface | | bgcolor="#ccffcc" | - extremely hard when high clay mineral content is present<br>- sometimes increased pH- values<br>- kaolin: risk of white residue on the surface | ||

|- | |- | ||

| Line 63: | Line 57: | ||

| bgcolor="#ccffcc" | - properties vary<br>- difficult to process<br>- low stability | | bgcolor="#ccffcc" | - properties vary<br>- difficult to process<br>- low stability | ||

|- | |- | ||

| bgcolor="#ccffcc" | Clay mineral-cellulose-sand- mixture (different mixtures, commercially available, predominantly on | | bgcolor="#ccffcc" | Clay mineral-cellulose-sand- mixture (different mixtures, commercially available, predominantly on bentonite basis) | ||

| bgcolor="#ccffcc" | - good stability<br>- machine processable<br>- strength and shrinkage can be controlled through composition | | bgcolor="#ccffcc" | - good stability<br>- machine processable<br>- strength and shrinkage can be controlled through composition | ||

| bgcolor="#ccffcc" | - any mix can become too heavy or too hard<br>- sometimes increased pH-values | | bgcolor="#ccffcc" | - any mix can become too heavy or too hard<br>- sometimes increased pH-values | ||

| Line 72: | Line 66: | ||

|} | |} | ||

Strictly not recommended are components: | Strictly not recommended are components: | ||

*preventing mass transport (risky are film- forming swelling media, or media with hydrophobic additives like | *preventing mass transport (risky are film- forming swelling media, or media with hydrophobic additives like agar-agar, gelatine, protein- gels, methyl cellulose), | ||

*containing or producing soluble salts | *containing or producing soluble salts | ||

| Line 81: | Line 75: | ||

*mineral binders (gypsum, lime, cement) or | *mineral binders (gypsum, lime, cement) or | ||

*surface- active substances (cleaning | *surface- active substances (cleaning, washing or surface-active agents) | ||

All | All poultice compositions provide some advantages and disadvantages, which are listed in the table above. For this reason the choice of material has to be tailored to each individual operation purpose, with regard to the boundary conditions. | ||

Further quality requirements need to | Further quality requirements need to be fulfilled according with demands: | ||

*Poultice components must not contain soluble salts (i.e.<nowiki><</nowiki> 0,1 M-% total salts) | *Poultice components must not contain soluble salts (i.e.,<nowiki><</nowiki> 0,1 M-% total salts) | ||

*The salt content of poultices has to be defined using the usual elution method on a minimum of 3 representative samples. The variation of the results from the arithmetic average has to be stated. The elution method using 20 times the amount of ''deionized water'', over a period of 24h at room temperature and under repeated agitation, has proved its value. | *The salt content of poultices has to be defined using the usual elution method on a minimum of 3 representative samples. The variation of the results from the arithmetic average has to be stated. The elution method using 20 times the amount of ''deionized water'', over a period of 24h at room temperature and under repeated agitation, has proved its value. | ||

*The ready-for-use mixture should have a pH-value of 6- 10 maximum (tested at 25 °C) | *The ready-for-use mixture should have a pH-value of 6-10 maximum (tested at 25 °C) | ||

*The poultice mixture should be easy to apply and should adhere well, but not cause any tension to the substrate. | *The poultice mixture should be easy to apply and should adhere well, but not cause any tension to the substrate. | ||

*The poultice mixture should be free from | *The poultice mixture should be free from dyes or coloring agents. | ||

*After treatment, it should be possible to remove the poultice without leaving any residue. | *After treatment, it should be possible to remove the poultice without leaving any residue. | ||

The poultice method can be carried out on the object in situ, or in the workshop. The above mentioned parameters can be varied, depending on the kind of poultice used, the existing climate, the surface structure, | The poultice method can be carried out on the object in situ, or in the workshop. The above mentioned parameters can be varied, depending on the kind of poultice used, the existing climate, the surface structure, etc. | ||

When applying | When applying poultices on vertical surfaces the adhesion is often a problem. The poultice should not slide off the surface through its proper weight thus possibly causing damage. Friable surfaces should therefore be consolidated before desalination. | ||

The application of | The application of a poultice should be repeated several times, however, after the second application its effectiveness is significantly reduced. As for the [[water bath desalination]] the success of the treatment depends on the pore structure, the kind of salts and salt forming ions present and their distribution, and should be controlled through analysis. | ||

More detailed references can be taken from the code of practice mentioned above. | More detailed references can be taken from the code of practice mentioned above. | ||

< | <gallery> | ||

<gallery caption=width="100%" cellspacing="0" cellpadding="4" border="1"> | <gallery caption=width="100%" cellspacing="0" cellpadding="4" border="1"> | ||

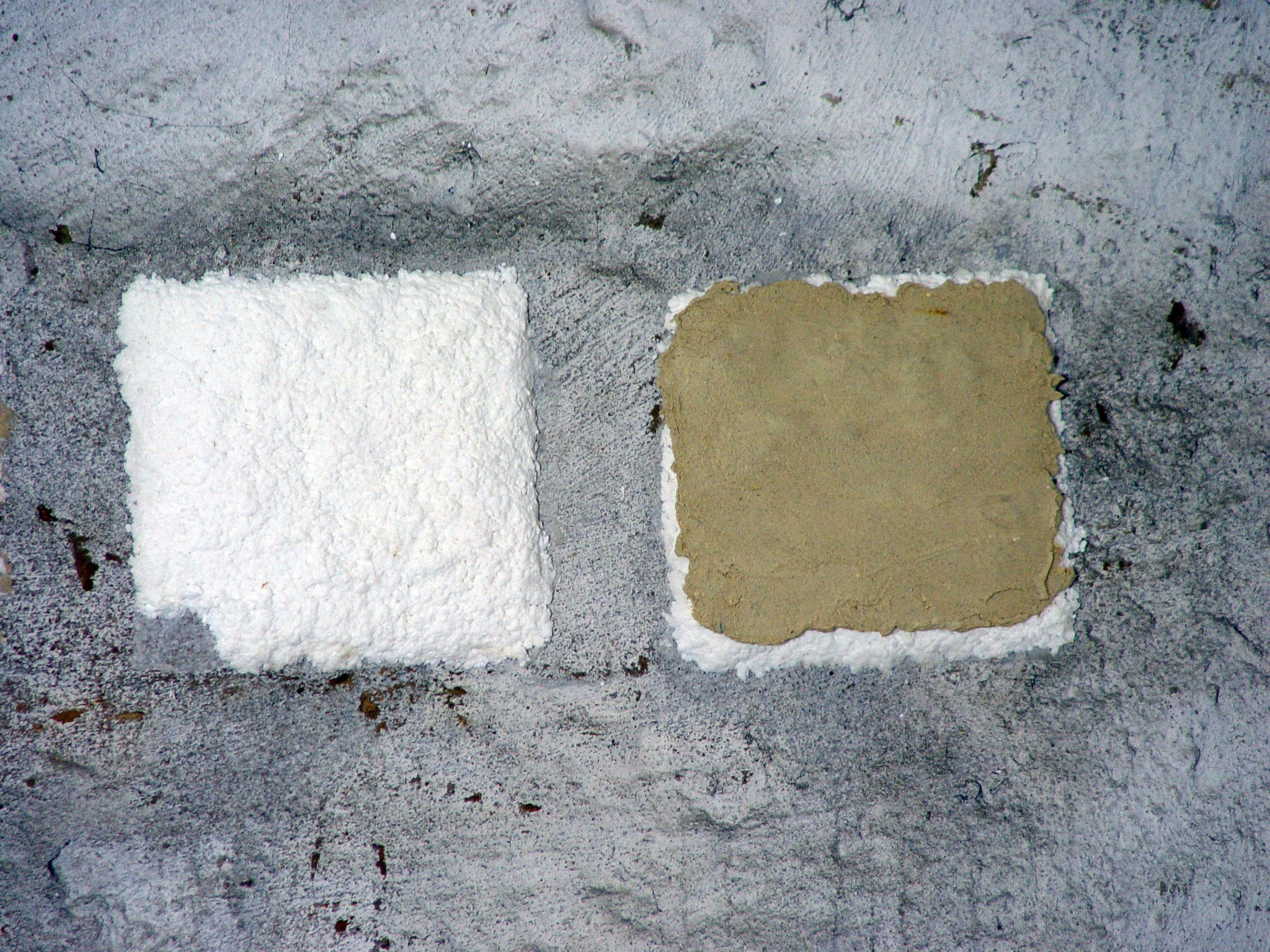

Image: | Image:Kompressen mit Putz-1.jpg|Figure 1: Poultices with and without render cover. | ||

Image: | Image:HiKR-Kompressen1.jpg |Figure 2: Desalination poultice with sampling locations marked. | ||

</gallery> | </gallery> | ||

<!-- | |||

== Weblinks == | |||

<references/> | |||

--> | --> | ||

== Literature == | |||

<biblist/> | |||

[[Category: | [[Category:Measures]][[Category:Desalination]][[Category:R-GGrassegger]] [[Category:R-SLaue]] [[Category:Schwarz,Hans-Jürgen]][[Category:approved]] | ||

Latest revision as of 10:43, 20 September 2013

Author: Hans-Jürgen Schwarz

English version by Sandra Leithäuser

back to Desalination

Permanently wet poultice[edit]

The poultice is kept moist during the application time. There is no, or only a small, moisture gradient so that salt transport is mainly due to diffusion. After some time, a salt concentration equilibrium is established between poultice and substrate. Permanently wet poultices should only be used in cases where a moisture gradient cannot be established, for example, a very damp wall. However, there are risks to this method, such that if a large area is being treated, salt may migrate back into areas of the substrate with a lower salt concentration. Also, long application times may enhance the development of microorganisms in the poultice material.

Drying Poultice[edit]

In this case, the poultice is allowed to dry out more or less completely, depending on the climatic conditions during application. Capillary transport and diffusion usually result in a flow towards the poultice, because of the rectified moisture gradient (first from the poultice to the substrate and then back into the poultice) as well as the salt concentration gradient. If the porosity of poultice and substrate is well matched, the capillary transport can be predominant. When gradual drying takes place, salts accumulate in the poultice material. For the treatment of relatively poorly soluble salts (e.g., gypsum) a combination of the two methods can be used. To begin with a permanently wet poultice is applied to dissolve the gypsum, then a drying poultice is applied. Due to the sheer number of influencing factors and their variation during the desalination treatment, no universally applicable procedure can be recommended. Only approximate values can be provided, and these have to be tailored to each individual case. Desalination poultices can be prepared from one or more components (listed below)and with deionized water to an appropriate consistency for application. Poultice materials that can be used are:

- Swellable materials from organic origin, no sealing properties, high water absorption and high water retention capacity (e.g., cellulose, paper pulp, aqueous gels).

- Mineral components with high specific surface area and a good ion exchange and adsorption properties (e.g., clay minerals and their mixtures, such as kaolin, bentonite etc.).

- Inert fillers (in combination with substances of the previous groups) to give the mixture properties such as stability, high porosity or a loose structure, to improve workability or decrease shrinkage, such as quartz sand, quartz flour, silica, good quality sand-rich in quartz, lightweight aggregates or equivalent).

- Other components that are highly porous, absorbent, flexible and inert mats and fleeces, such as foams, paper, textiles, etc.

Table 1 lists the materials recommended by the WTA.

The injection poultice procedure[edit]

This procedure [Friese.etal:1993]Title: Entsalzung von Ziegelmauerwerk mit dem Injektionskompressenverfahren

Author: Friese, Peter; Hermoneit, Bernd is carried out by introducing the water for desalination via the interior of the wall. For this purpose holes are drilled into the masonry or its joints and a pipe is fitted through it to the center of the wall or just beyond the salt contaminated layer, and water is sent through it. At the injection point, the water disperses spherically and when two water- spheres of adjacent injection points overlap, a capillary water flow is generated from the interior of the wall towards the surface of the masonry on which a poultice is applied. A disadvantage, however, is that holes need to be drilled and this is a decision that needs serious evaluation with regards to ethics and history of the building.

is carried out by introducing the water for desalination via the interior of the wall. For this purpose holes are drilled into the masonry or its joints and a pipe is fitted through it to the center of the wall or just beyond the salt contaminated layer, and water is sent through it. At the injection point, the water disperses spherically and when two water- spheres of adjacent injection points overlap, a capillary water flow is generated from the interior of the wall towards the surface of the masonry on which a poultice is applied. A disadvantage, however, is that holes need to be drilled and this is a decision that needs serious evaluation with regards to ethics and history of the building.

When using this method it is very important to assess the structure of the wall well enough and to know exactly which materials were used and if the masonry has a different core. The introduction of water into the structure could lead to an increase in weight, leakage of unknown substances, water seepage in other areas of the building, or uncontrollable swelling. Also the amount of water introduced needs to be controlled.

| Poultice composition | Advantages | Disadvantages |

| Pure cellulose fibers of different length | - pH-neutral - flexible, soft, adherent - high water absorption |

- low stability - risk of mold formation |

| Bentonite, attapulgite, kaolin, pure or mixed with cellulose | - high water retention capacity - kaolin: in solution almost neutral,hardly any alkali can be mobilized |

- extremely hard when high clay mineral content is present - sometimes increased pH- values - kaolin: risk of white residue on the surface |

| Clays (no further specification) | - high water retention capacity | - extremely hard - sometimes increased pH-values - contamination and soluble proportion unpredictable |

| Newspaper or paper pulp predominantly cellulose/ hemicellulose/ lignin |

- high water absorption | - bleaches, additives and colors could be introduced |

| Cellulose-mixtures with high sand content | - with good quality sands pH-neutral | - properties vary - difficult to process - low stability |

| Clay mineral-cellulose-sand- mixture (different mixtures, commercially available, predominantly on bentonite basis) | - good stability - machine processable - strength and shrinkage can be controlled through composition |

- any mix can become too heavy or too hard - sometimes increased pH-values |

| Clay minerals-light aggregates-mix, sometimes with cellulose | - good stability - machine processable - low shrinkage, low density |

- sometimes increased pH-values - can become too hard, depending on the mix - kaolin: risk of white residue on the surface |

Strictly not recommended are components:

- preventing mass transport (risky are film- forming swelling media, or media with hydrophobic additives like agar-agar, gelatine, protein- gels, methyl cellulose),

- containing or producing soluble salts

- mineral binders (gypsum, lime, cement) or

- surface- active substances (cleaning, washing or surface-active agents)

All poultice compositions provide some advantages and disadvantages, which are listed in the table above. For this reason the choice of material has to be tailored to each individual operation purpose, with regard to the boundary conditions.

Further quality requirements need to be fulfilled according with demands:

- Poultice components must not contain soluble salts (i.e.,< 0,1 M-% total salts)

- The salt content of poultices has to be defined using the usual elution method on a minimum of 3 representative samples. The variation of the results from the arithmetic average has to be stated. The elution method using 20 times the amount of deionized water, over a period of 24h at room temperature and under repeated agitation, has proved its value.

- The ready-for-use mixture should have a pH-value of 6-10 maximum (tested at 25 °C)

- The poultice mixture should be easy to apply and should adhere well, but not cause any tension to the substrate.

- The poultice mixture should be free from dyes or coloring agents.

- After treatment, it should be possible to remove the poultice without leaving any residue.

The poultice method can be carried out on the object in situ, or in the workshop. The above mentioned parameters can be varied, depending on the kind of poultice used, the existing climate, the surface structure, etc.

When applying poultices on vertical surfaces the adhesion is often a problem. The poultice should not slide off the surface through its proper weight thus possibly causing damage. Friable surfaces should therefore be consolidated before desalination.

The application of a poultice should be repeated several times, however, after the second application its effectiveness is significantly reduced. As for the water bath desalination the success of the treatment depends on the pore structure, the kind of salts and salt forming ions present and their distribution, and should be controlled through analysis.

More detailed references can be taken from the code of practice mentioned above.

Literature[edit]

| [Friese.etal:1993] | Friese, Peter; Hermoneit, Bernd (1993): Entsalzung von Ziegelmauerwerk mit dem Injektionskompressenverfahren. In: Bautenschutz und Bausanierung, 16 (2), 26-27 |  |

| [WTA_3-13-01_D:2003] | WTA_3-13-01 D (2003): WTA-Merkblatt 3-13-01 D, Zerstörungsfreies Entsalzen von Naturstein und anderen porösen Baustoffen mittels Kompressen, WTA-Merkblatt, 13. |  |