Gravimetric methods

Authors: Hans-Jürgen Schwarz

back to Moisture Measurement

Abstract[edit]

The gravimetric method is the most common method for the determination of the material moisture content. The different possibilities of drying the sample are presented on an introductory level.

Introduction[edit]

The gravimetric method [Nagel:2002]Title: Thermogravimetrische Materialfeuchtebestimmung

Author: Nagel, Horst belongs to the destructive methods, where different samples are taken from an object or building, i.e. in the shape of drill core samples.

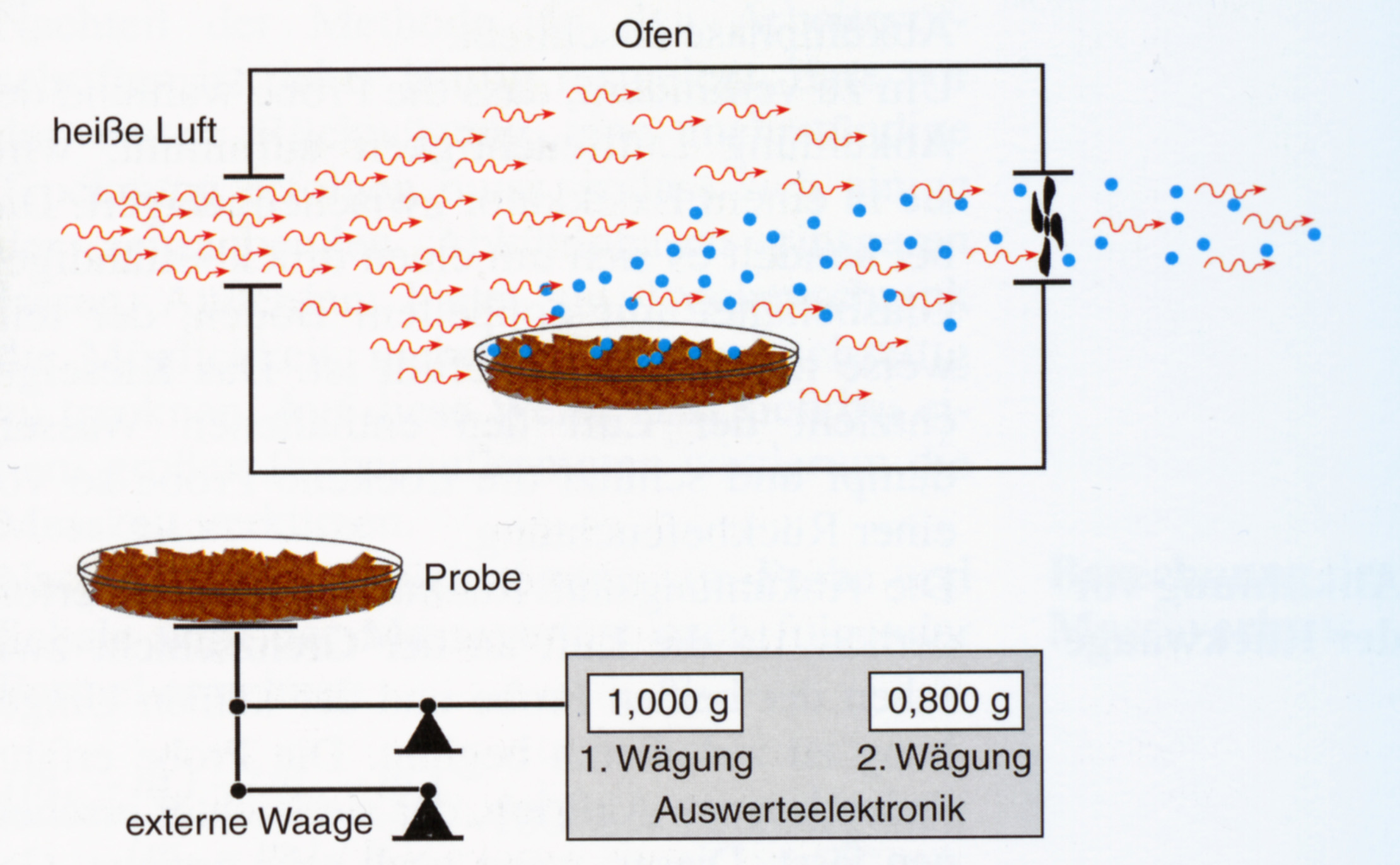

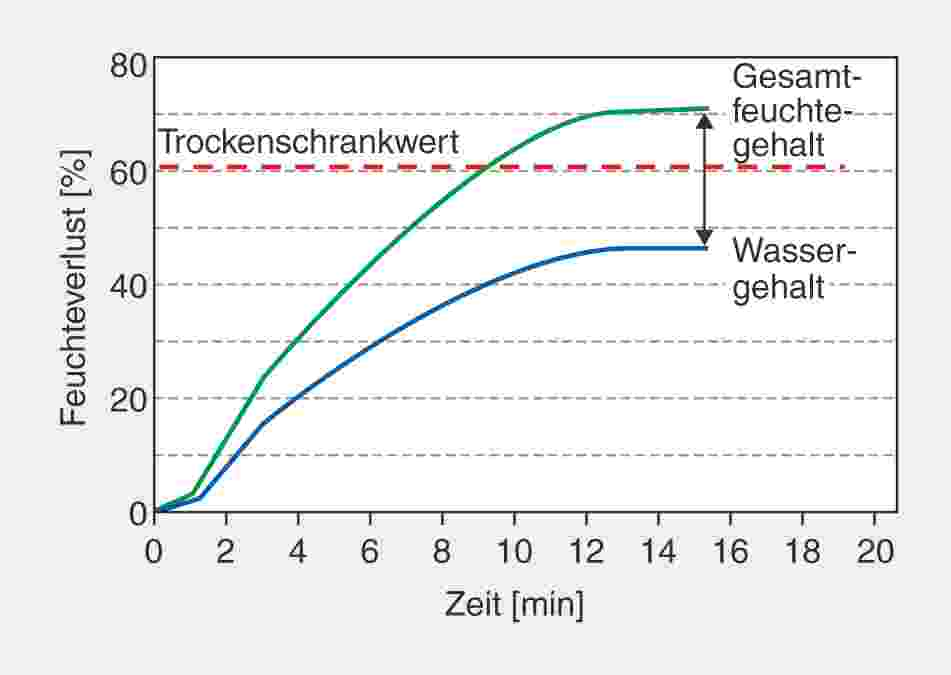

The sample is weighed, then dried to constant weight and weighed again. The difference in mass denotes the moisture content of the sample. The gravimetric Darr method is the internationally standardized method and serves as a reference method for other measuring methods.

belongs to the destructive methods, where different samples are taken from an object or building, i.e. in the shape of drill core samples.

The sample is weighed, then dried to constant weight and weighed again. The difference in mass denotes the moisture content of the sample. The gravimetric Darr method is the internationally standardized method and serves as a reference method for other measuring methods.

The accuracy of the method depends on a number of factors. Firstly, at removal of the sample a change in moisture content may happen, e.g. due to heating during the drilling. The sample has to be packed absolutely airtight directly after collection, because even at room temperature significant losses occur. The amount of material needed for a sample depends on the homogeneity of the material. The minimum lies at around 1 g for fine aggregate samples.

The most common drying method is by heating inside a cabinet dryer. The drying temperature for most materials is 105 °C. It is a prerequisite that no chemical change of the material occurs at this temperature. Gypsum, for example, needs a drying temperature of 40°C, because it looses some of its chemically bound water at 45°C and is then converted into ß-hemihydrate. The relative humidity (RH) inside the drying chamber must be kept at sufficiently low levels. If ambient air is used for the exchange, even at low drying temperatures the high RH in summer may produce significant residual moisture in the sample and cause measuring errors.

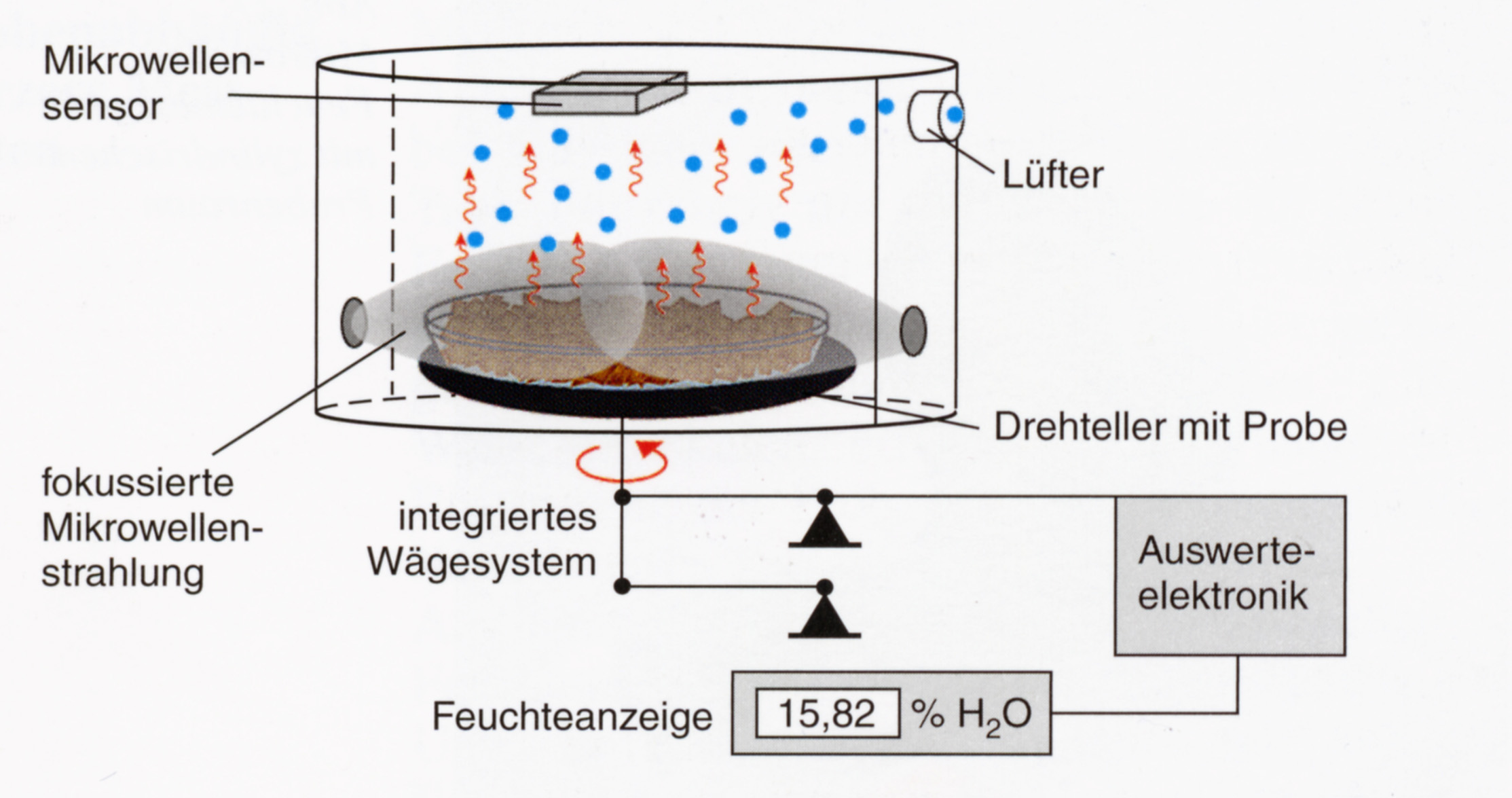

A shortening of the drying time can be achieved by microwave drying, because practically the whole sample is brought up to drying temperature within a very short period of time. However, it requires some experience to meter the microwave power properly.

A falsification of the results can occur due to hygroscopic water absorption in between the two weighings. Normally, an accuracy of ± 0.2 - 0.5% can be achieved when working carefully.

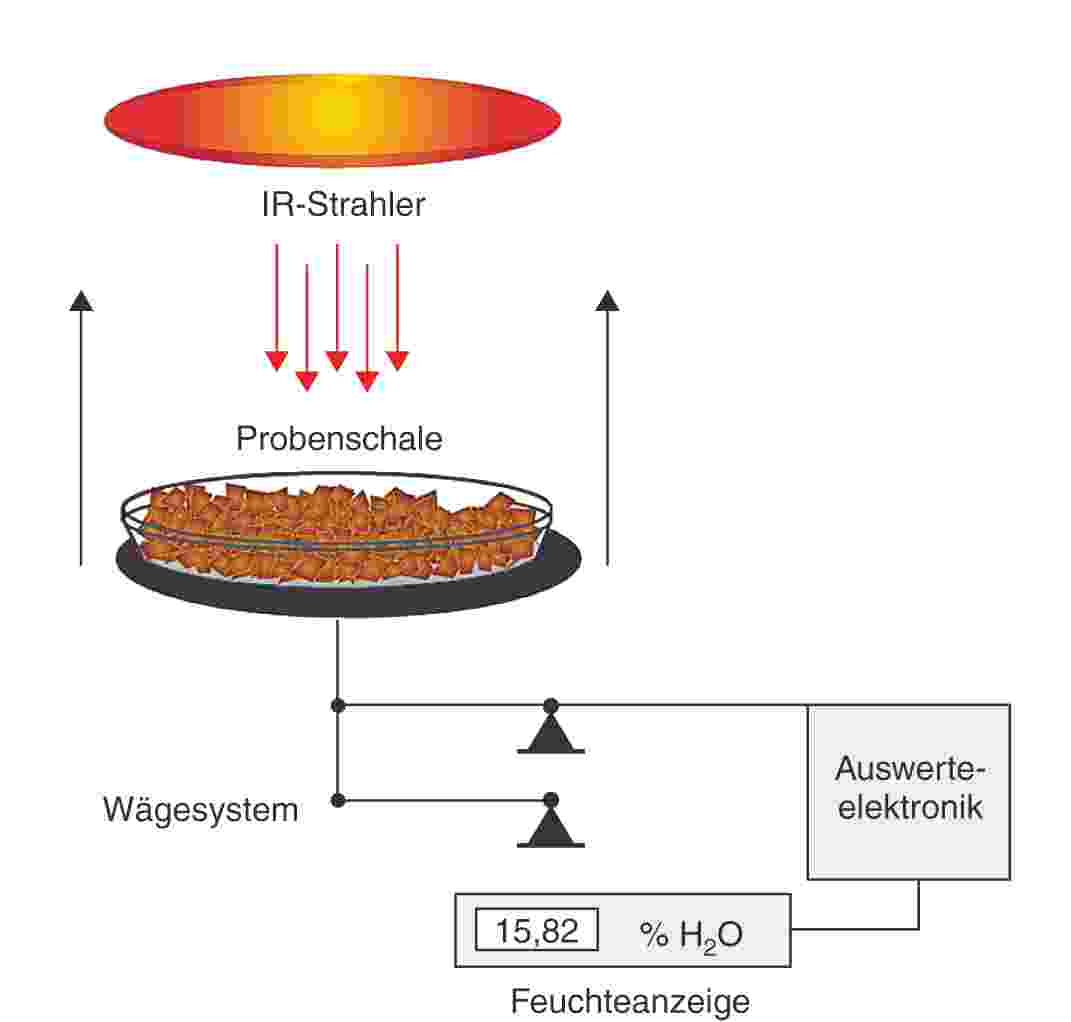

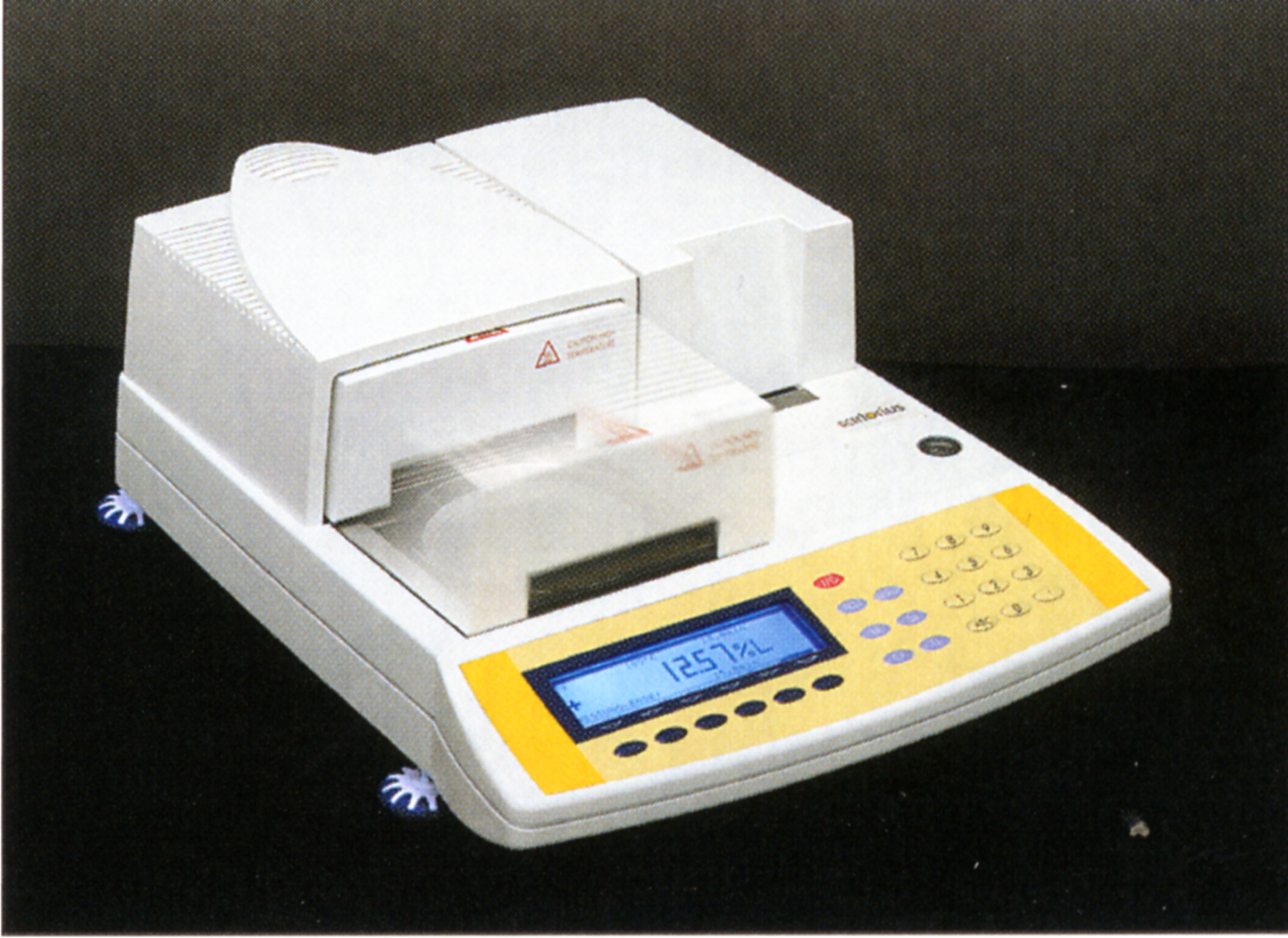

Furthermore, the drying of the sample using infrared radiation is possible. This option is present in many devices that are commercially available.

Instead of drying through temperature increase, samples can also be dried in the vacuum. For this purpose the sample is placed into a desiccator, which has been evacuated. The vapor pressure is lowered using e.g. hygroscopic salts (phosphor pentoxide) or silica gel

Main disadvantage of the gravimetric method is that it is destructive and cannot be used very well in situ.

Literature[edit]

| [Nagel:2002] | Nagel, Horst (2002): Thermogravimetrische Materialfeuchtebestimmung, Verlag Moderne Industrie |  |

--SLeithaeuser 00:15, 28 January 2013 (CET)